Multi functional high frequency canned diaphragm valve

working principle

Multi functional high frequency canned diaphragm valve has a dual-station cylinder and a flow-adjustable filling valve.

For fast filling and to prevent spillage or spillage of the bottle.

The flow rate is maximum when 1 cylinder is working;

When the cylinder is working, the flow rate is the smallest, and the flow rate adjustment device can also be used to adjust the flow rate when the flow 2# cylinder is working.

Recommended setting

- cylinder opens when the liquid is filled to 70%-80% liquid level.

- cylinders are opened to fill to a reasonable level.

Technical advantages

With high efficiency, high precision canning, material zero overflow, long life (pressure 2bar up to 8 million times), flow adjustable, dual cylinder design.

Technical specifications

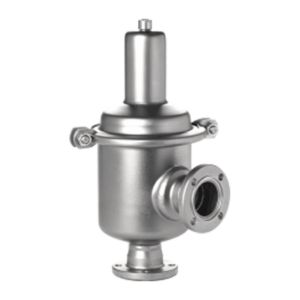

Mini manual diaphragm valves are mainly used in materials sampling, biological systems, laboratories and other projects.

The valve has special advantages in filling equipment such as pharmaceuticals or beverages. When the working pressure is 3ba, the number of opening and closing times can reach 1.5 million life.

- SIZE: 1/4 “-3/4”, DN6-DN15

- Standard BPE 3A DIN ISO IDF

- Certification PED/97/23/EC, 3A/54-04/1580, FDA.177.2600

- Maximum temperature: -20 to 150 ° C (depending on the sealing material) (stainless steel actuator)

- Maximum temperature: -20 to 130 ° C (depending on the sealing material) (plastic actuator)

- Maximum pressure: one direction (DELTA P=100%)

Normally closed rubber 8bar, PTFE 6bar (optional)

Normally closed rubber 6bar, PTFE 4.5bar (standard)

Normally open and double acting rubber 8bar, PTFE 6bar - Replacement of different actuators can meet higher pressure levels

- Forged valve body: 1.4404/316L/1.4435 BN2

- Casting valve body: 1.4404/316L

- Connection method: welding, clamp, flange, thread

- Operation mode: manual and pneumatic

Reviews

There are no reviews yet.