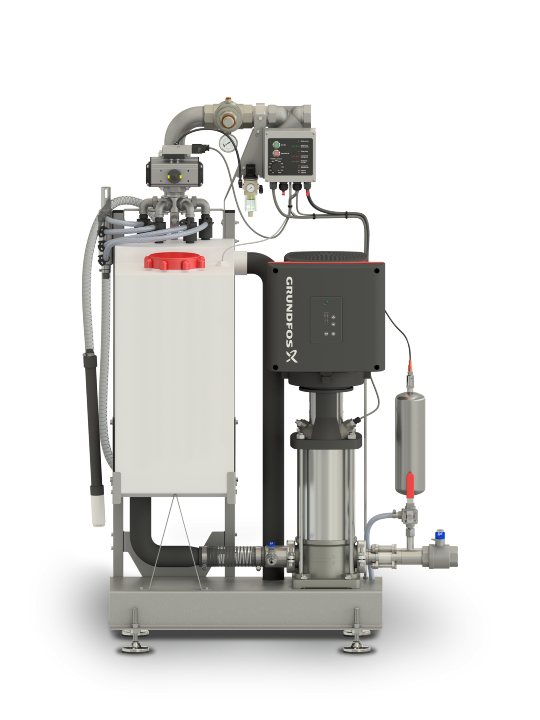

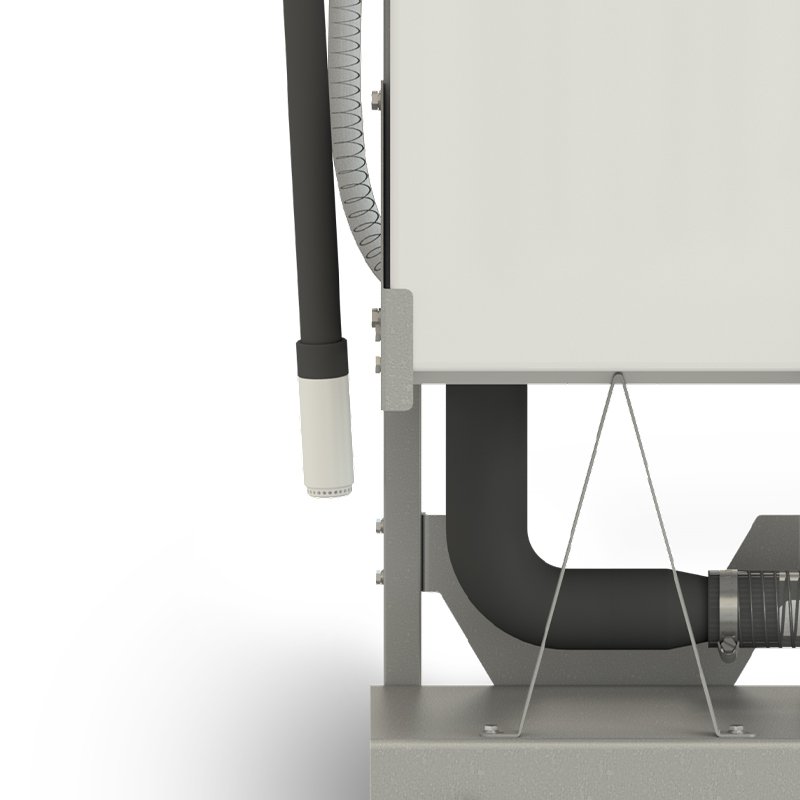

CP chemical pump station

The floor-mounted CP range consists of three compact, frequency-controlled pump stations, which mix the chemical product with water in an integrated tank.

The prediluted product is then boosted by a chemical resistant centrifugal pump and supplied through the piping system to the workstations. No storage of chemical cans in the production area and no heavy lifting.

The range is available in three variants: CP10 for up to 10 users/workstations, CP30 for up to 30 users/workstations and CP40 for up to 40 users/workstations. All variants have a booster capacity of 6-12 bar.

Adjustment of the dosing is done on ONE dosing valve regardless of the number of injectors, ensuring consistent chemical concentration for all workstations.

Welded joints in chemical tank below fluid level reduces the risk of leakages. The use of corrosion and chemical resistant materials such as stainless steel AISI316 and PTFE optimizes the service life on a wide range of components.

The floor-mounted chemical pump station must be placed in a separate technical room or the like to screen it from the processing environment.

Available in different voltages, currents, and threads.

Features

- Supplies up to 40 users/workstations with prediluted chemical product

- One chemical inlet for one concentrated chemical product

- Easy dosing adjustment ensures consistent chemical concentration

- Adjustable set point

- Automatic start and stop

- Energy-saving Grundfos IE5 pump motors

- Frequency-controlled pump with soft start and stop

- Option of control unit with empty tank indication

- Easy to service

- Produced in high quality materials with high chemical resistance

Low-pressure cleaning with boosted water offers a range of benefits

Significant reduction in cleaning time

Reduced water and chemical consumption

Less wear on processing equipment and affected surfaces

Improved work environment

Low maintenance and service requirements

Reviews

There are no reviews yet.