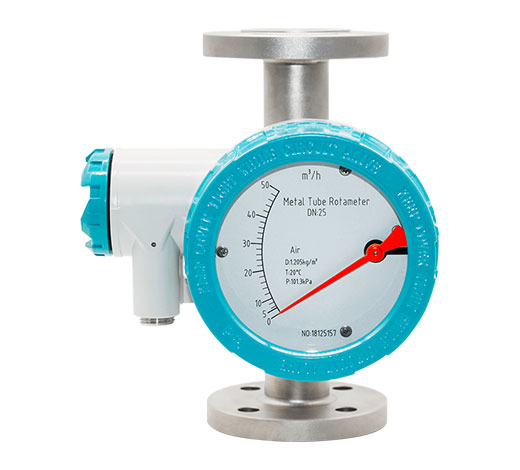

Vertical Pointer Variable Area Flowmeter

LZ series intelligent Vertical Pointer Variable Area Flowmeter adopts the international advanced Honeywell without contact and no hysteresis detecting changes in the Angle of magnetic field of magnetic sensor, and with high performance MCU,which can realize LCD display:the instantaneous flow, total flow,loop current.environment temperature,damping time,small signalremoval.Optional 4~20mA tranmission(with HART communication),pulse output, high and low limit alarm output function,etc,the type of intelligent signal transmitter has high precision and reliability,which can fully replace the same type imported instrument, and it also has high price performance, parameter standardization online and power failure protection,etc features.

- Range ratio: 10:1(Special type 20:1).

- Accuracy class: 2.5(Special type 1.5% or 1.0%).

- Working pressure: DN15~DN50 PN16 (Special type 2.5MPa).

- Medium temperature: Normalized type -80℃~+220℃.

- Ambient temperature: -40℃~+120℃(Remote display without LCD≤85℃).

Advantages

Vertical Pointer Variable Area Flowmeter advantages:

1. Fully welded stainless steel body,Durable using.

2. Independent of medium’s physical and chemical states such as conductivity, dielectric constants, etc.

3. Applicable for all kinds of medium environment such as corrosive, toxic and explosive one.

4. Interface measurement or level measurement of 2 kinds of medium with different density.

5.Easy-to-read displays on all flow meter types)

6.Two-wire 4~20mADC signal output available;

Application

Vertical Pointer Variable Area Flowmeter Applications

Vertical Pointer Variable Area Flowmeter is mainly suitable for small and medium flow measurement of single-phase liquid or gas with small and medium pipe diameter, low noise and Reynolds number of acetic acid,like Air,Water,lubricating oil,Steam,Hydrogen,O2,etc,and many other Liquid or gas in the Chemical,Pharmaceutical, Petrochemical,Food,Metallurgical Industry ,etc.

Technical Data

Table 1: Vertical Pointer Variable Area Flowmeter Data Sheet

| Measuring range | Water (20℃) 16~150000 l/h.

Air(0.1013MPa 20℃) 0.5~4000 m3/h. |

| Range ratio | 10:1(Special type 20:1). |

| Accuracy class | 2.5(Special type 1.5% or 1.0%). |

| Working pressure | DN15~DN50 PN16 (Special type 2.5MPa).

DN80~DN150 PN10 (Special type 1.6MPa). Pressure rating of jacket 1.6MPa. |

| Medium temperature | Normalized type -80℃~+220℃.

High-temperature type 300℃. Lined with FEP type ≤85℃. |

| Ambient temperature | -40℃~+120℃(Remote display without LCD≤85℃).

(Remote display with LCD≤70℃). |

| Dielectric viscosity | 1/4” NPT, 3/8” NPT 1/2” NPT≤5mPa.s

3/4” NPT,1” NPT ≤250mPa.s |

| Output | Standard signal: two-wire system 4 ~ 20mA (with HART communication).

Standard signal: three-wire system 0 ~ 10mA. Alarm signal:1.Two-way relay output. 2.One-way or two-approach switches . Pulse signal output: 0-1KHz isolated output. |

| Process connection | Standard type:24VDC±20%.

AC type:220VAC(85~265VAC) (optional). |

| Connection mode | Flange

Thread Tri-clamp |

| Levels of protection | IP65/IP67. |

| Ex-mark | Intrinsically safe:ExiaIICT3~6. Exd type:ExdIICT4~6. |

Table 2: Vertical Pointer Variable Area Flowmeter Flow Range

| Caliber

(mm) |

Work number | Flow range | Pressure loss kpa | ||||

| Water L/h | Air m3/h | Water Kpa | Air | ||||

| Normal type | Anti-corrossion type | Normal type Anti-corrossion type |

Normal type | Anti-corrossion type | |||

| 15 | 1A | 2.5~25 | — | 0.07~0.7 | 6.5 | – | 7.1 |

| 1B | 4.0~40 | 2.5~25 | 0.11~1.1 | 6.5 | 5.5 | 7.2 | |

| 1C | 6.3~63 | 4.0~40 | 0.18~1.8 | 6.6 | 5.5 | 7.3 | |

| 1D | 10~100 | 6.3~63 | 0.28~2.8 | 6.6 | 5.6 | 7.5 | |

| 1E | 16~160 | 10~100 | 0.48~4.8 | 6.8 | 5.6 | 8.0 | |

| 1F | 25~250 | 16~160 | 0.7~7.0 | 7.0 | 5.8 | 10.8 | |

| 1G | 40~400 | 25~250 | 1.0~10 | 8.6 | 6.1 | 10.0 | |

| 1H | 63~630 | 40~400 | 1.6~16 | 11.1 | 7.3 | 14.0 | |

| 25 | 2A | 100~1000 | 63~630 | 3~30 | 7.0 | 5.9 | 7.7 |

| 2B | 160~1600 | 100~1000 | 4.5~45 | 8.0 | 6.0 | 8.8 | |

| 2C | 250~2500 | 160~1600 | 7~70 | 10.8 | 6.8 | 12.0 | |

| 2D | 400~4000 | 250~2500 | 11~110 | 15.8 | 9.2 | 19.0 | |

| 40 | 4A | 500~5000 | 300~3000 | 12~120 | 10.8 | 8.6 | 9.8 |

| 4B | 600~6000 | 350~3500 | 16~160 | 12.6 | 10.4 | 16.5 | |

| 50 | 5A | 630~6300 | 400~4000 | 18~180 | 8.1 | 6.8 | 8.6 |

| 5B | 1000~10000 | 630~6300 | 25~250 | 11.0 | 9.4 | 10.4 | |

| 5C | 1600~16000 | 1000~10000 | 40~400 | 17.0 | 14.5 | 15.5 | |

| 80 | 8A | 2500~25000 | 1600~16000 | 60~600 | 8.1 | 6.9 | 12.9 |

| 8B | 4000~40000 | 2500~25000 | 80~800 | 9.5 | 8.0 | 18.5 | |

| 100 | 10A | 6300~63000 | 4000~40000 | 100~1000 | 15.0 | 8.5 | 19.2 |

| 150 | 15A | 20000~100000 | — | 600~3000 | 19.2 | — | 20.3 |

Table 3: Vertical Pointer Variable Area Flowmeter Model Selection

| QTLZ | X | X | X | X | X | X | X | X | X |

| Indicator | Code | ||||||||

| Local indicator | Z | ||||||||

| LCD indicator with ouput | D | ||||||||

| Norminal diameter | Code | ||||||||

| DN15 | -15 | ||||||||

| DN20 | -20 | ||||||||

| DN25 | -25 | ||||||||

| DN40 | -40 | ||||||||

| DN50 | -50 | ||||||||

| DN80 | -80 | ||||||||

| DN100 | -100 | ||||||||

| DN150 | -150 | ||||||||

| Structure | Code | ||||||||

| Bottom-top | / | ||||||||

| Left-right (horizontal) | H1 | ||||||||

| Right-left (horizontal) | H2 | ||||||||

| Side-side | AA | ||||||||

| Bottom -side | LA | ||||||||

| Thread connection | S | ||||||||

| Tri-clamp | M | ||||||||

| Body material | Code | ||||||||

| 304SS | R4 | ||||||||

| 316LSS | R6L | ||||||||

| Hastelloy C | Hc4 | ||||||||

| Titanium | Ti | ||||||||

| Liner F46(PTFE) | F | ||||||||

| Monel | M | ||||||||

| Indicator type | Code | ||||||||

| Iinear indicator(pointer indication) | M7 | ||||||||

| Nonlinear indicator(LCD Display) | M9 | ||||||||

| Combination function(only for LCD display) | Code | ||||||||

| 24VDC with 4~20mA output | S | ||||||||

| 24VDC with HART communication | Z | ||||||||

| Battery power | D | ||||||||

| Additional function | Code | ||||||||

| Measuring tube with thermal preservation / heat insulation jacket | T | ||||||||

| Measure medium temperature higher than 120.C | HT | ||||||||

| Ex-proof: | Code | ||||||||

| With | W | ||||||||

| Without | N | ||||||||

| Alarm | Code | ||||||||

| One alarm | K1 | ||||||||

| Two alarm | K2 | ||||||||

| None | N | ||||||||

Installation

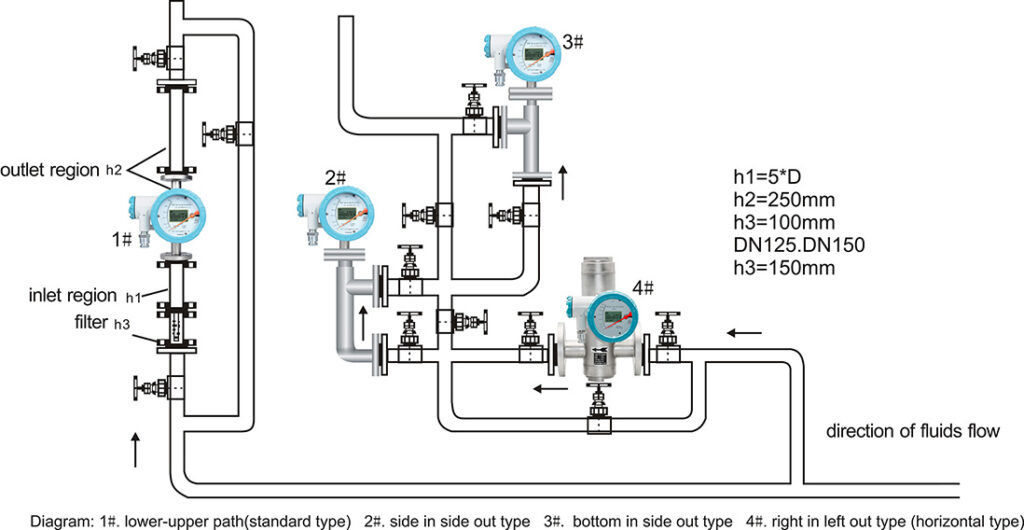

Metal Tube Rotameter Installaion

Installed flowmeter should guarantee the entry ≥5DN straight pipe section,export straight pipe section not less than 250mm ;if the medium containing ferromagnetic material,magnetic filter should be installed in front of the flowmeter。(see magnetic filter and straight pipe section diamension diagram

- For flow meter installed,ensure the measuring pipe perpendicularity is better than 5 and should be equipped with bypass,easy to maintain and clean and does not affect production..

- Monitoring and control system in the control valve,should be installed downstream of the flowmeter.For gas measurement,Should ensure the working pressure is not less than 5 times of pressure loss of the flowmeter, to make stable work of the flowmeter.

- Before install the flowmeter,The pipe should be welding slag purging clean;When installation to remove locking component in the flow meter;when used after installation,Slowly open the control valve,Avoid shock damage flow meter

Reviews

There are no reviews yet.